|

PLEASE PATRONIZE OUR SPONSORS!

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

Seems my K301 has been bored .010 over already, checking the bore it seems to be in spec and good to go. My confusion comes from the fact that the rings I removed from it one has .084 end gap and the other .054? Can the rings wear this bad with no cylinder wear or did someone put standard rings back in it when they rebuilt it?

|

|

#2

|

|||

|

|||

|

sounds like thats what they did ,,i ran into that on a .020 to .030 bore ,it must have used some oil

|

|

#3

|

|||

|

|||

|

Didn't really seem to but I didn't run it much before I tore it down so I don't really know. Did seem to smoke alittle but nothing serious, I don't even know how it was running truthfully the carb was in such horrible shape. Ill just plan to put new rings and deglaze then just seemed odd for just the rings to wear so badly.

|

|

#4

|

||||

|

||||

|

Quote:

The circumference of the +.010 bore is 10.634 and the standard bore is 10.603, a difference of .031 I would say somebody was completely clueless on proper gapping techinques and just plain screwed up. Did you use the piston upside down to make sure the rings were square in the bore? |

|

#5

|

|||

|

|||

|

As far as the measuring, I leave it up to people like Jeff, Dale my buddy Phile that do this stuff all the time so I cant help you there.

I will say that yes the rings can wear with out wearing the bore. Its in one of Kohlers failure tests. Its due to over heating. I belive this is what the failure was on Dannys command. When I did the leak down on it I had about 98% compression on the #2 cylinder and on #1 it was just over 50% on kohlers guage. I do remember that that head had a mouse nest in it when I got the cyclops tractor I used as a doner. |

|

#6

|

|||

|

|||

|

Quote:

|

|

#7

|

||||

|

||||

|

Quote:

It's easier using a piston

|

|

#8

|

|||

|

|||

|

Quote:

|

|

#9

|

|||

|

|||

|

Jeff

Thats how I do mine. Works real well and you know your in straight. |

|

#10

|

|||

|

|||

|

Did you measure the cylinder bore in 6 places like the Kohler manual shows?

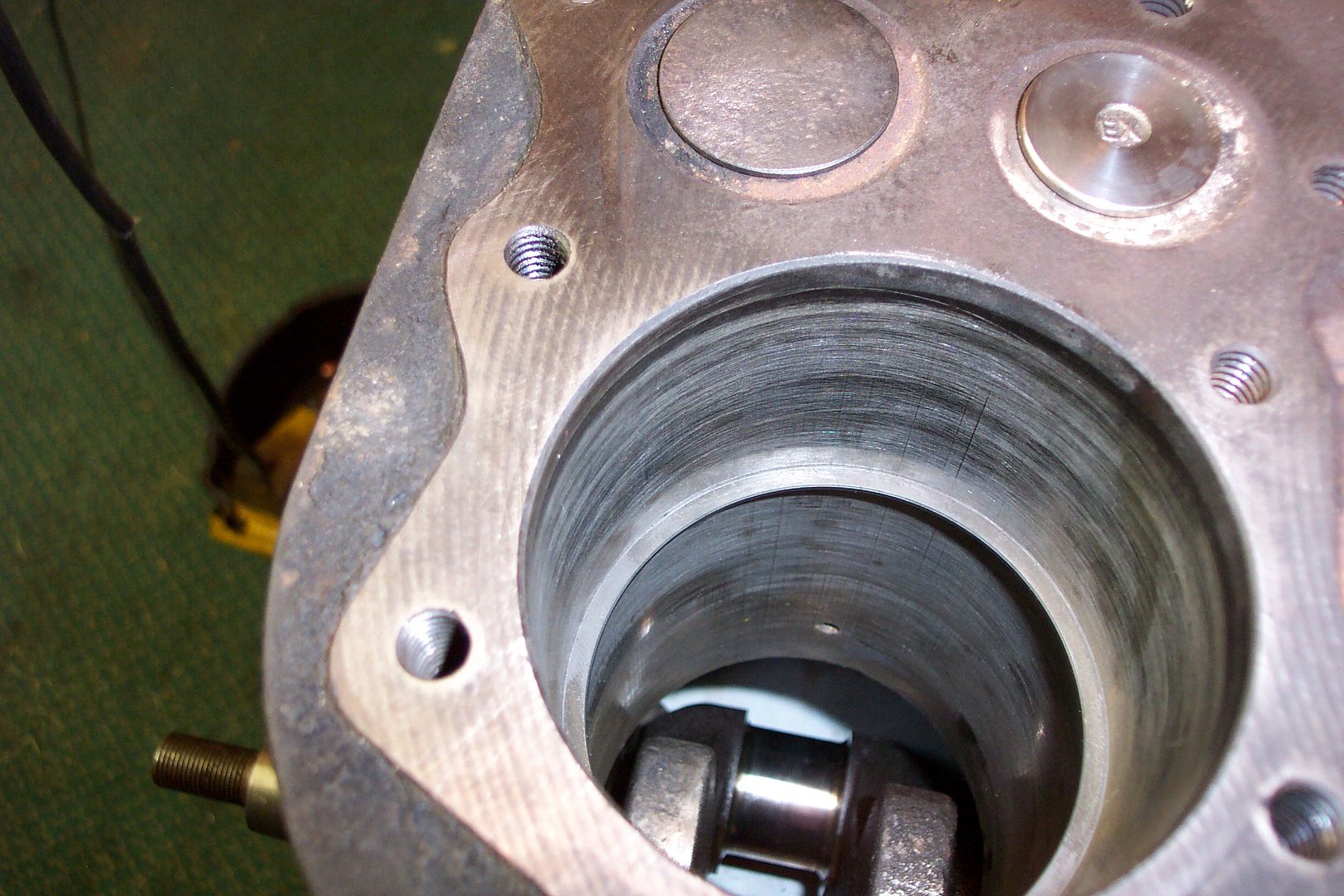

What were the measurements if you did? Dud you hone the cylinder bore? Is it me or am I seeing up and down marks in the cylinder bore???? The up and down start about an inch down to the bottom on the cylinder wall. The piston skirt rides in that area. The cylinder may need bored if the marks are there. The engine will use oil unless the marks are removed. Can you post of the piston???? |

|

|

|

Cub Cadet is a premium line of outdoor power equipment, established in 1961 as part of International Harvester. During the 1960s, IH initiated an entirely new line of lawn and garden equipment aimed at the owners rural homes with large yards and private gardens. There were a wide variety of Cub Cadet branded and after-market attachments available; including mowers, blades, snow blowers, front loaders, plows, carts, etc. Cub Cadet advertising at that time harped on their thorough testing by "boys - acknowledged by many as the world's worst destructive force!". Cub Cadets became known for their dependability and rugged construction.

MTD Products, Inc. of Cleveland, Ohio purchased the Cub Cadet brand from International Harvester in 1981. Cub Cadet was held as a wholly owned subsidiary for many years following this acquisition, which allowed them to operate independently. Recently, MTD has taken a more aggressive role and integrated Cub Cadet into its other lines of power equipment.

This website and forum are not affiliated with or sponsored by MTD Products Inc, which owns the CUB CADET trademarks. It is not an official MTD Products Inc, website, and MTD Products Inc, is not responsible for any of its content. The official MTD Products Inc, website can be found at: http://www.mtdproducts.com. The information and opinions expressed on this website are the responsibility of the website's owner and/or it's members, and do not represent the opinions of MTD Products Inc. IH, INTERNATIONAL HARVESTER are registered trademark of CNH America LLC

All material, images, and graphics from this site are the property of www.onlycubcadets.net. Any unauthorized use, reproductions, or duplications are prohibited unless solely expressed in writing.

Cub Cadet, Cub, Cadet, IH, MTD, Parts, Tractors, Tractor, International Harvester, Lawn, Garden, Lawn Mower, Kohler, garden tractor equipment, lawn garden tractors, antique garden tractors, garden tractor, PTO, parts, online, Original, 70, 71, 72, 73, 76, SO76, 80, 81, 86, 100, 102, 104, 105, 106, 107, 108,109, 122, 123, 124, 125, 126, 127, 128, 129, 147, 149, 169, 182, 282, 382, 482, 580, 582, 582 Special, 680, 682, 782, 782D, 784, 800, 805, 882, 982, 984, 986, 1000, 1015, 1100, 1105, 1110, 1200, 1250, 1282, 1450, 1512, 1604, 1605, 1606, 1610, 1615, 1620, 1650, 1710, 1711, 1712, 1806, 1810, 1811, 1812, 1912, 1914.