|

PLEASE PATRONIZE OUR SPONSORS!

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

Have this old 149 that I bought last winter. Used it very little since purchase. Just seen that it had worn the S/G belt badly. S/G pulley and Front Engine pulley seem to be out of alignment. Is it possible to move the front engine pulley away from the engine about 1/8 inch? Would this affect the pto going back on properly? Also had to put a bolt through the inside lift arm to raise and lower the mower deck. I will try to attach photos. Does the lift setup look normal? Thanks in advance for all your help.

Bob |

|

#2

|

||||

|

||||

|

The 125 I just bought is out of alignment too. If you don't mind I'm going to pay attention to this thread.

__________________

Grandpa's 1961 "O" w/ mowing deck, 169, 149, 147, 1000, 125 w/creeper and 3pt, 1250 w/ 44A deck, 1650, Frankenstien 1250, Great Grandpas 1968 Cadet 125 w/original QA-36, CCC 1711, Model 2 tiller, QA-42 and a QA-42A Snowthrower, Cozy cab May not be as much as others, but we're still building our fleet! There are more to come! Connor |

|

#3

|

||||

|

||||

|

If you remove the two set screws on the pto pulley you can move it forward.

They are located in the holes closest to the pulley. They are allen head and that is the easy part as the pulley does not move that easy after being on there for 40 years.Use plenty of pb blaster and gently tap the pulley forward.

__________________

Up to 533 and counting... I give up updating my profile! |

|

#4

|

||||

|

||||

|

Quote:

click for larger pic |

|

#5

|

|||

|

|||

|

Quote:

|

|

#6

|

||||

|

||||

|

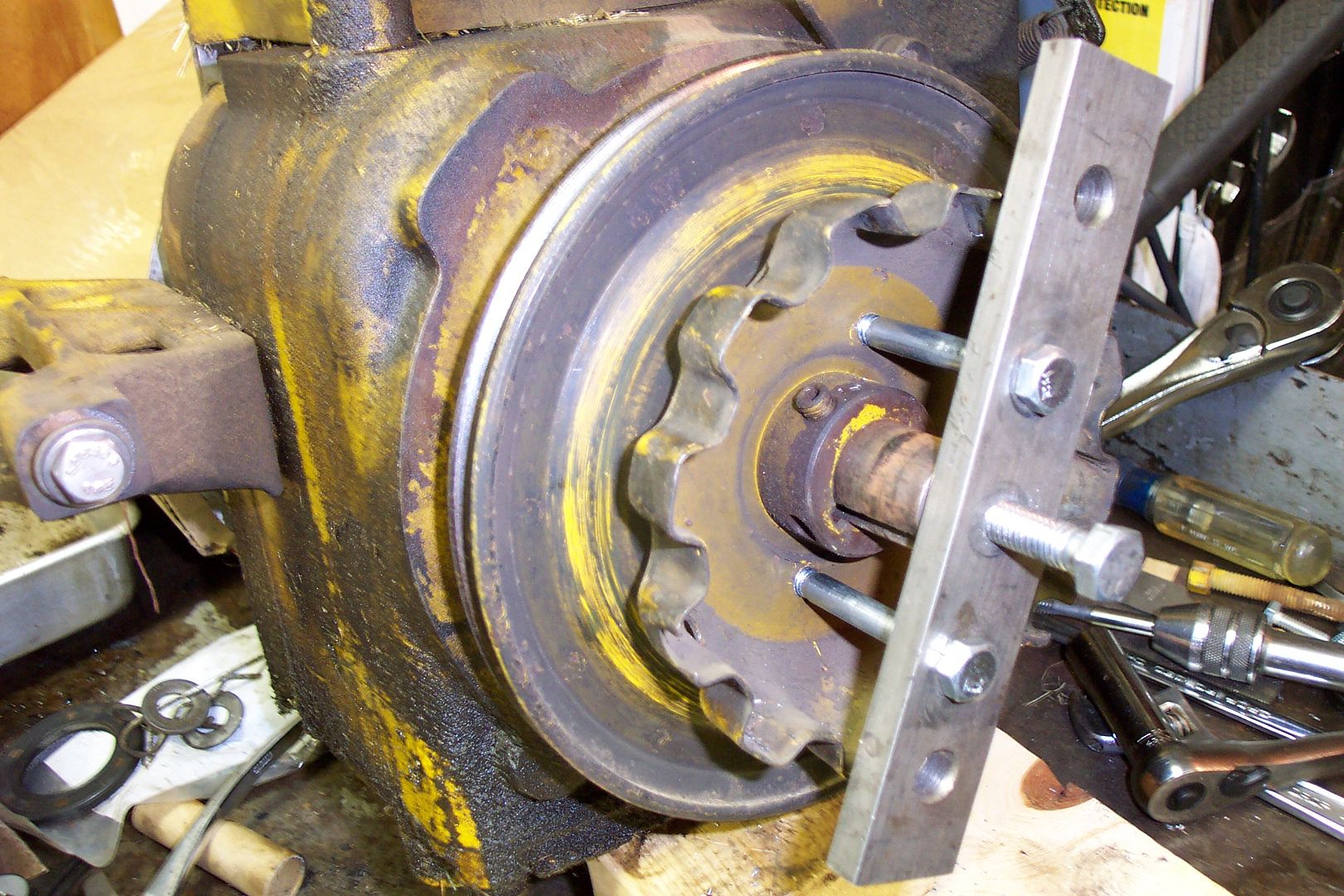

Oh, it gets better

click for bigger pic Sockets made for a great bearing puller I spaced the 5/16" holes for the bolt at 3/8" wider than the bearing diameter. I used two 3/8" drive 1/2" sockets ( correct socket for 5/16" bolts) to grab the bearing. After loosening the eccentric, it comes right off. Using the puller to pull the pulley off, just drill the pulley with a "F" drill ( .257) and tap the pulley 5/16-18NC. |

|

#7

|

||||

|

||||

|

Quote:

|

|

#8

|

||||

|

||||

|

I have no idea but it might also be possible to pull the S/G pulley off and put back on "inside out".

Maybe there is an offset in the pulley. |

|

#9

|

||||

|

||||

|

It's hard to see in your pics but do you have the PTO bearing on the crank? The bearing should be flush with the end of the crank and the pulley sets up against the back of the bearing. If the S/G pulley is not inline after adjusting the bearing and crank pulley, then the pulley is wrong on the S/G. I had a pulley alignment issue on my 126 that ended up being the crank pulley and bearing being out of position.

__________________

Adam 1964 Model 100 w/ K301 12hp and custom hydraulics 1972 Model 149 turned 129 w/ K301 12hp, triple hydraulics, 66 series clone |

|

#10

|

||||

|

||||

|

Quote:

__________________

Up to 533 and counting... I give up updating my profile! |

|

|

|

Cub Cadet is a premium line of outdoor power equipment, established in 1961 as part of International Harvester. During the 1960s, IH initiated an entirely new line of lawn and garden equipment aimed at the owners rural homes with large yards and private gardens. There were a wide variety of Cub Cadet branded and after-market attachments available; including mowers, blades, snow blowers, front loaders, plows, carts, etc. Cub Cadet advertising at that time harped on their thorough testing by "boys - acknowledged by many as the world's worst destructive force!". Cub Cadets became known for their dependability and rugged construction.

MTD Products, Inc. of Cleveland, Ohio purchased the Cub Cadet brand from International Harvester in 1981. Cub Cadet was held as a wholly owned subsidiary for many years following this acquisition, which allowed them to operate independently. Recently, MTD has taken a more aggressive role and integrated Cub Cadet into its other lines of power equipment.

This website and forum are not affiliated with or sponsored by MTD Products Inc, which owns the CUB CADET trademarks. It is not an official MTD Products Inc, website, and MTD Products Inc, is not responsible for any of its content. The official MTD Products Inc, website can be found at: http://www.mtdproducts.com. The information and opinions expressed on this website are the responsibility of the website's owner and/or it's members, and do not represent the opinions of MTD Products Inc. IH, INTERNATIONAL HARVESTER are registered trademark of CNH America LLC

All material, images, and graphics from this site are the property of www.onlycubcadets.net. Any unauthorized use, reproductions, or duplications are prohibited unless solely expressed in writing.

Cub Cadet, Cub, Cadet, IH, MTD, Parts, Tractors, Tractor, International Harvester, Lawn, Garden, Lawn Mower, Kohler, garden tractor equipment, lawn garden tractors, antique garden tractors, garden tractor, PTO, parts, online, Original, 70, 71, 72, 73, 76, SO76, 80, 81, 86, 100, 102, 104, 105, 106, 107, 108,109, 122, 123, 124, 125, 126, 127, 128, 129, 147, 149, 169, 182, 282, 382, 482, 580, 582, 582 Special, 680, 682, 782, 782D, 784, 800, 805, 882, 982, 984, 986, 1000, 1015, 1100, 1105, 1110, 1200, 1250, 1282, 1450, 1512, 1604, 1605, 1606, 1610, 1615, 1620, 1650, 1710, 1711, 1712, 1806, 1810, 1811, 1812, 1912, 1914.