|

PLEASE PATRONIZE OUR SPONSORS!

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

#11

|

|||

|

|||

|

Quote:

Sorry Jeff

__________________

Project Uncle Dick Cub Cadet 70 http://www.onlycubcadets.net/forum/s...ght=Uncle+Dick |

|

#12

|

|||

|

|||

|

Here are the parts that will be used to rebuild the clutch:

First thing that needs done is to replace the pins and bushing in the 3 pin driver. Pins  Bushing  Reinstalling bushing:  pins:  3 pin driver is ready to install.

__________________

Project Uncle Dick Cub Cadet 70 http://www.onlycubcadets.net/forum/s...ght=Uncle+Dick |

|

#13

|

|||

|

|||

|

I like to take the 3 pin driver and slide it over the driveshaft to make sure it turns freely.

I aslo take the clutch disc and slide it over the 3 pin driver to make sure everything is alined. I like to use brake clean to remove oil from clutch disc and pressure plates.   The first thing I like to do is install the pin that holds the pressure plate hub.  Next thing to make sure the pressure plate hub slides over the pin. The pressure plate did not slide over the pin.

__________________

Project Uncle Dick Cub Cadet 70 http://www.onlycubcadets.net/forum/s...ght=Uncle+Dick |

|

#14

|

|||

|

|||

|

Right side is ok.

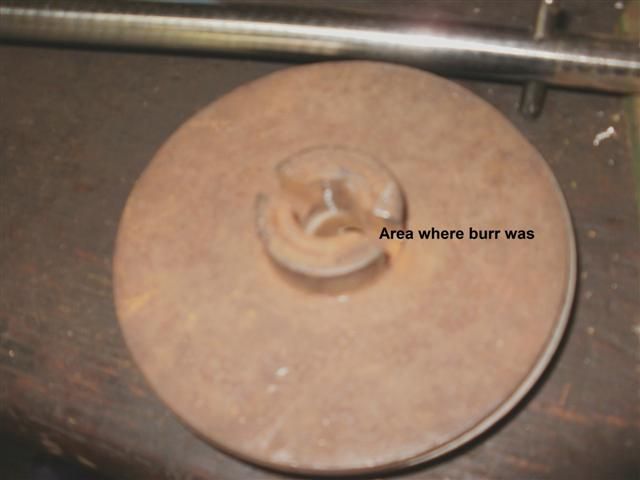

Left side has a burr.   The hub had a burr on the one side where the pin goes. The pressure plate hub now slides over the pin.  The pressure plate hub goes on the driveshaft.  Next is the clutch friction disc.  Next is the locating pressure assembly and drive pin into place.

__________________

Project Uncle Dick Cub Cadet 70 http://www.onlycubcadets.net/forum/s...ght=Uncle+Dick |

|

#15

|

|||

|

|||

|

I will install the 3 pin driver to drive shaft to check if everything spins freely.

Plus it centers the friction disc. I will check the clutch lever for wear.  The shinny spots are where the throw out bearing rides. The clutch lever and compression (teaser) are next to be installed.  Throw out bearing goes on next.

__________________

Project Uncle Dick Cub Cadet 70 http://www.onlycubcadets.net/forum/s...ght=Uncle+Dick |

|

#16

|

|||

|

|||

|

There are several different compression springs that you can use in your Cub Cadet clutch. Cub Cadet Classics has a blue spring that has 500 to 600 pound rating. The red spring has a 800 pound rating. The yellow spring has a 1120 pound rating. The stock spring has 225 to 250 pound rating. I set my clutches so my Wife and grand kids can push the clutch in. The red spring is too much and the stock spring isn't strong enough. I found on a tractor pull site this spring that has a 500 rating. It was before the blue spring was found plus it is cheaper. The spring is half of a field cultivator spring. One problem with this spring is the inside diameter is too big. I use a piece of pipe as a spacer with this spring.

My IH Cub Cadet 100 has this spring set up in for the last 3 years with no problems. Install the spacer on drive shaft.  Washer is first them the spring.  Next is a washer and 2 split collars.  Some may be asking why I use split collars instead of the pin that cub Cadet used. The hole in the drive shaft is a weak spot. I'm trying to eliminate weak areas. Next the clutch assembly goes in my clutch spring compressor.  The clutch spring is compress to the same spot where the pin thru the driveshaft location was. Both collars are tighten.  The second collar is more for insurance so the they don't slip on the drive shaft. Hopefully everyone notice the safety pin in my clutch spring compressor. there is plenty of stored energy in that drive shaft. This picture shows the spring that holds the clutch pedal up.  It was missing. Clutch is installed back in the 100.

__________________

Project Uncle Dick Cub Cadet 70 http://www.onlycubcadets.net/forum/s...ght=Uncle+Dick |

|

#17

|

|||

|

|||

|

This was the main reason why the work to the 100 was done.

The 2 nuts were welded to the inside of the frame. I have several different attachments that mount where the mule drive connects. I purchase these from Jeff in Pa.  It makes mounting attachments to the 100 much easier. ( Thanks Jeff!!!)

__________________

Project Uncle Dick Cub Cadet 70 http://www.onlycubcadets.net/forum/s...ght=Uncle+Dick |

|

#18

|

|||

|

|||

|

The material that the driveshaft is made out of is 4140 material.

The clutch is a Kevlar/fiberglass composite material. This sounds overkill for a 10 horse power Cub Cadet. The plans are to increase the horse power next year. I hope I was able to show you the way I been building clutches. There are different ways to build one. This set up works for me. You will have a few more parts if you are working on a wide frame clutch. Keep track of where they go. The above clutch rebuild was done on a narrow frame clutch assembly. There are few items that are different between a narrow frame clutch assembly and wide frame-quiet line assembly. Parts that are different: Driveshaft length The throw out bearing part number on models 70-100-71-102-122-72-104-124-73-106-126 is 941-3056. The throw out bearing part number on models 86-108-128-580-582-800-1000-1050-1200-1535-1604-1606 and 1806 is 703-0600. Models 86-108-128-580-582-800-1000-1050-1200-1535-1604-1606 and 1806 have a spring spacer in the drive shaft.

__________________

Project Uncle Dick Cub Cadet 70 http://www.onlycubcadets.net/forum/s...ght=Uncle+Dick |

|

#19

|

|||

|

|||

|

Quote:

__________________

Project Uncle Dick Cub Cadet 70 http://www.onlycubcadets.net/forum/s...ght=Uncle+Dick |

|

#20

|

|||

|

|||

|

I found the part number(s) for the spring I used.

500 pound clutch spring PECP1511A1 (New Holland) EP1511 (AGCO) You can go to a New Holland or AGCO dealer to see if they have the part or they should be able to order one. The spring needs to be cut in 2.

__________________

Project Uncle Dick Cub Cadet 70 http://www.onlycubcadets.net/forum/s...ght=Uncle+Dick |

Cub Cadet is a premium line of outdoor power equipment, established in 1961 as part of International Harvester. During the 1960s, IH initiated an entirely new line of lawn and garden equipment aimed at the owners rural homes with large yards and private gardens. There were a wide variety of Cub Cadet branded and after-market attachments available; including mowers, blades, snow blowers, front loaders, plows, carts, etc. Cub Cadet advertising at that time harped on their thorough testing by "boys - acknowledged by many as the world's worst destructive force!". Cub Cadets became known for their dependability and rugged construction.

MTD Products, Inc. of Cleveland, Ohio purchased the Cub Cadet brand from International Harvester in 1981. Cub Cadet was held as a wholly owned subsidiary for many years following this acquisition, which allowed them to operate independently. Recently, MTD has taken a more aggressive role and integrated Cub Cadet into its other lines of power equipment.

This website and forum are not affiliated with or sponsored by MTD Products Inc, which owns the CUB CADET trademarks. It is not an official MTD Products Inc, website, and MTD Products Inc, is not responsible for any of its content. The official MTD Products Inc, website can be found at: http://www.mtdproducts.com. The information and opinions expressed on this website are the responsibility of the website's owner and/or it's members, and do not represent the opinions of MTD Products Inc. IH, INTERNATIONAL HARVESTER are registered trademark of CNH America LLC

All material, images, and graphics from this site are the property of www.onlycubcadets.net. Any unauthorized use, reproductions, or duplications are prohibited unless solely expressed in writing.

Cub Cadet, Cub, Cadet, IH, MTD, Parts, Tractors, Tractor, International Harvester, Lawn, Garden, Lawn Mower, Kohler, garden tractor equipment, lawn garden tractors, antique garden tractors, garden tractor, PTO, parts, online, Original, 70, 71, 72, 73, 76, SO76, 80, 81, 86, 100, 102, 104, 105, 106, 107, 108,109, 122, 123, 124, 125, 126, 127, 128, 129, 147, 149, 169, 182, 282, 382, 482, 580, 582, 582 Special, 680, 682, 782, 782D, 784, 800, 805, 882, 982, 984, 986, 1000, 1015, 1100, 1105, 1110, 1200, 1250, 1282, 1450, 1512, 1604, 1605, 1606, 1610, 1615, 1620, 1650, 1710, 1711, 1712, 1806, 1810, 1811, 1812, 1912, 1914.