|

PLEASE PATRONIZE OUR SPONSORS!

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

#21

|

||||

|

||||

|

you going t use cub axels and hydro's?

|

|

#22

|

||||

|

||||

|

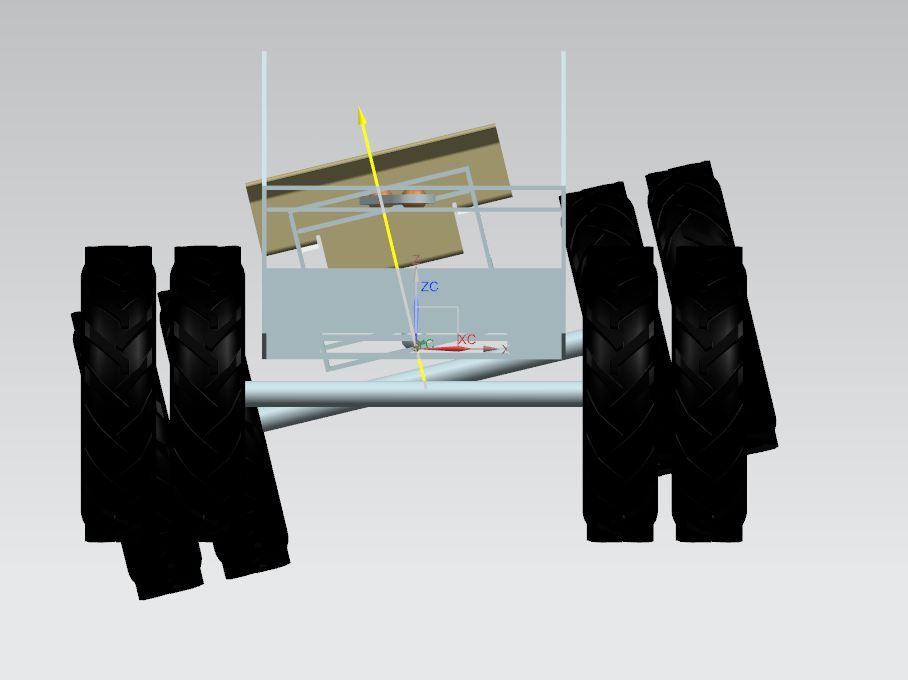

Great advice, and I think a pillow block bearing on each part of the driveshaft that's connected to one of the transmissions would be a good idea. I can see a rather long unsupported length in your latest picture...that will put some bending loads on the shaft it isn't designed for, particularly if the shaft binds, and it would probably vibrate a lot too if there is any slop between the U-joint shaft, sleeve, and input shaft.

|

|

#23

|

|||

|

|||

|

Yep, I have 2 - 1711 rear axle assemblies.

|

|

#24

|

|||

|

|||

|

Quote:

|

|

#25

|

||||

|

||||

|

One other issue is keeping the shafts parallel with a U-Joint type drive line. Otherwise you will need to use a CV type joint.

__________________

2264 with 54 GT deck 1641 AKA Black Jack with a 402-E Haban Sickle bar mower JD317 dump truck BX2670 with FEL |

|

#26

|

|||

|

|||

|

Why is that a problem with 2 U joints, but not with 1?

|

|

#27

|

||||

|

||||

|

In the drawing I did I should have explained that the black lines represent the driver and driven shafts and the red line is the drive shaft itself. Picture a U-Joint at the intersection of the red and black lines. This will explain how U-Joints work in more detail.

http://www.hurst-drivelines.com/file...roc_111606.pdf

__________________

2264 with 54 GT deck 1641 AKA Black Jack with a 402-E Haban Sickle bar mower JD317 dump truck BX2670 with FEL |

|

#28

|

|||

|

|||

|

Quote:

The input into the drive line & the output have to remain parallel? So a full size articulating tractor only have one U joint in-line with the pivot point? What happens wen the front & back rock? Something has to give, another U joint would be needed. Rock:

|

|

#29

|

||||

|

||||

|

My suggestion is that you find an articulating loader and take some pics of the drive line so that you can copy how they designed the drive line.

__________________

2264 with 54 GT deck 1641 AKA Black Jack with a 402-E Haban Sickle bar mower JD317 dump truck BX2670 with FEL |

|

#30

|

|||

|

|||

|

A couple of good working articulaters,

|

|

|

|

Cub Cadet is a premium line of outdoor power equipment, established in 1961 as part of International Harvester. During the 1960s, IH initiated an entirely new line of lawn and garden equipment aimed at the owners rural homes with large yards and private gardens. There were a wide variety of Cub Cadet branded and after-market attachments available; including mowers, blades, snow blowers, front loaders, plows, carts, etc. Cub Cadet advertising at that time harped on their thorough testing by "boys - acknowledged by many as the world's worst destructive force!". Cub Cadets became known for their dependability and rugged construction.

MTD Products, Inc. of Cleveland, Ohio purchased the Cub Cadet brand from International Harvester in 1981. Cub Cadet was held as a wholly owned subsidiary for many years following this acquisition, which allowed them to operate independently. Recently, MTD has taken a more aggressive role and integrated Cub Cadet into its other lines of power equipment.

This website and forum are not affiliated with or sponsored by MTD Products Inc, which owns the CUB CADET trademarks. It is not an official MTD Products Inc, website, and MTD Products Inc, is not responsible for any of its content. The official MTD Products Inc, website can be found at: http://www.mtdproducts.com. The information and opinions expressed on this website are the responsibility of the website's owner and/or it's members, and do not represent the opinions of MTD Products Inc. IH, INTERNATIONAL HARVESTER are registered trademark of CNH America LLC

All material, images, and graphics from this site are the property of www.onlycubcadets.net. Any unauthorized use, reproductions, or duplications are prohibited unless solely expressed in writing.

Cub Cadet, Cub, Cadet, IH, MTD, Parts, Tractors, Tractor, International Harvester, Lawn, Garden, Lawn Mower, Kohler, garden tractor equipment, lawn garden tractors, antique garden tractors, garden tractor, PTO, parts, online, Original, 70, 71, 72, 73, 76, SO76, 80, 81, 86, 100, 102, 104, 105, 106, 107, 108,109, 122, 123, 124, 125, 126, 127, 128, 129, 147, 149, 169, 182, 282, 382, 482, 580, 582, 582 Special, 680, 682, 782, 782D, 784, 800, 805, 882, 982, 984, 986, 1000, 1015, 1100, 1105, 1110, 1200, 1250, 1282, 1450, 1512, 1604, 1605, 1606, 1610, 1615, 1620, 1650, 1710, 1711, 1712, 1806, 1810, 1811, 1812, 1912, 1914.