|

PLEASE PATRONIZE OUR SPONSORS!

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

#61

|

|||

|

|||

|

Enjoying watching your build, I recently bought a Johnson model 10 on a WH and its just not up to the task.

I am going to put mine on a 149 as well. Keep up the good work!! Randy

__________________

2 original cub cadets  1 100's 2 149's 1 73 1 2182 |

|

#62

|

|||

|

|||

|

Looks like your taking a similar path I did to mount mine on my 1650. I got an extra set of external brake mounting brackets, and that's how the rear of my bracket is attached. Like your Ubolt idea as well.

I use the front of the mule drive to make my front bracket that the the downtubes mount to. That same bracket is also where the pump is mounted to mate to the PTO. For some reason these are the only pictures I can find at the moment.

__________________

1872 W/ Kwik Way loader 1650 W/ Dual Hydraulics, and rear lift Cadplans Caddigger qa36a blower, tiller, and snow blade Gannon Earthcavator |

|

#63

|

|||

|

|||

|

So many different ways to arrive at the same thing, getting a loader mounted to a tractor! I enjoy looking at everyone else's design!!! I have used all the pics I could find on the net and on this forum to offer the "brainstorming" for what I have come up with. Most of my design is based on steel I have laying around.

I liked the idea of using the brake mounts I have seen used, I went with the U bolts to be different and my thinking was the loader is going to roll the sub-frame so having the main length wise supports under the rear offered good support. I'm going to machine up solid spacer inserts and weld to the tube that the U bolts will go through, this will keep the tube from crushing. One thing I found using the tube was width of sub-frame, I had to go wider than I thought due to the rear axle tubes and in hindsight I probably should have stuck with flat stock like so many of you have done. I wanted my front 4" wide down supports to catch the tube on the angle across the tube to make a clean weld. I'm now going to have to add flat supports from the tube to catch the down supports and box them in as the down support only catches the inside of the tube. I'm to far along now so I will continue with what I am using. I wish I would have a bending attachment for plate to use on my hydraulic press I like the bent frame work and supports, oh well another project I need to build! I've seen the front supports to the front end and some to right in front of the down mounts, I like the shorter arms I am going with, not sure I can say why though? My plan is to use an angle plate cut down for the support to "lay on" instead of a stud sticking out. More welding but as I said in an earlier post that is some of my goal on this project to use my Eastwood 200 Tig for welding practice. I would be interested in seeing how everyone has mounted their pump to a front mule drive, this is my plan after looking at some of the other designs I am following. I do not though have any clear pics of how it was done just long distance shots. Anyone want to add pics of their pump setup please do so. Thanks! |

|

#64

|

|||

|

|||

|

unfortunately I blew the motor in the loader tractor, and I don't think I can get any clear pics for you of the mule drive.

Basically I permanently bolted the front piece of the mule drive to the frame, I think i might have drilled 1 extra hole per side, then I Took the existing mounting bracket I had for the pump lined up the pump to to PTO welded the new bracket together. The lines are coming out of the front side of the tractor. I will caution you that i had a hard time finding a belt because it needed to be so short - about 12 inches in circumference. I ended up ordering an assortment from vbelts4less.com which were only about $4.00 a piece. Locally ag belts are about $12 each. Here's the press brake I used to bend the brackets: http://www.swagoffroad.com/20-TON-Fi...-Kit_p_86.html Much like you and the tig, i was just playing around with my new toy more than anything, the bender certainly is necessary to put one of these together.

__________________

1872 W/ Kwik Way loader 1650 W/ Dual Hydraulics, and rear lift Cadplans Caddigger qa36a blower, tiller, and snow blade Gannon Earthcavator |

|

#65

|

|||

|

|||

|

Thanks for the mule drive info! Kinda what I was thinking from some of the pics I have seen.

Couple of updates from the weekend. Sub-frame is tack welded and installed, found out Tig doesn't like rusty steel but, it was all I had. More support will be welded in place on the front mounts to box it all in. Made up some mounting plates for my uprights as they came with something not original, still have to weld on the back stud, the c-clamps are temp. Still thinking about my down support mounting. Think I'm going to weld 90 degree plates out from the top of the front supports (wings) with supports underneath. The down supports will bolt flat to these "wings", originally I was going to extend the wings forward and drill some holes and bolt them fast. Problem with that is the engine sits right there and there is little to no access to that area with the engine in-place. So that idea is out . . . I find myself spending more time standing back thinking about making things work than actually doing the work! |

|

#66

|

|||

|

|||

|

For the front down supports, I bent up some wings that I welded to the mule drive. they extend up and out. Situated them so I didn't need to extend/ shorten the stock downtubes that came with the loader, and so that I could still get my sidepanels off.

I too was kind of weary of the mounting brackets your working on. Looks like your pretty much replicating what's stock. They seem to work fine.

__________________

1872 W/ Kwik Way loader 1650 W/ Dual Hydraulics, and rear lift Cadplans Caddigger qa36a blower, tiller, and snow blade Gannon Earthcavator |

|

#67

|

|||

|

|||

|

I was leery of the stock mounting setup but now that I have them made and clamped on they work surprisingly well! Once they are actually bolted fast they will be even better. I picked up some 1/2" bolts today to make my studs.

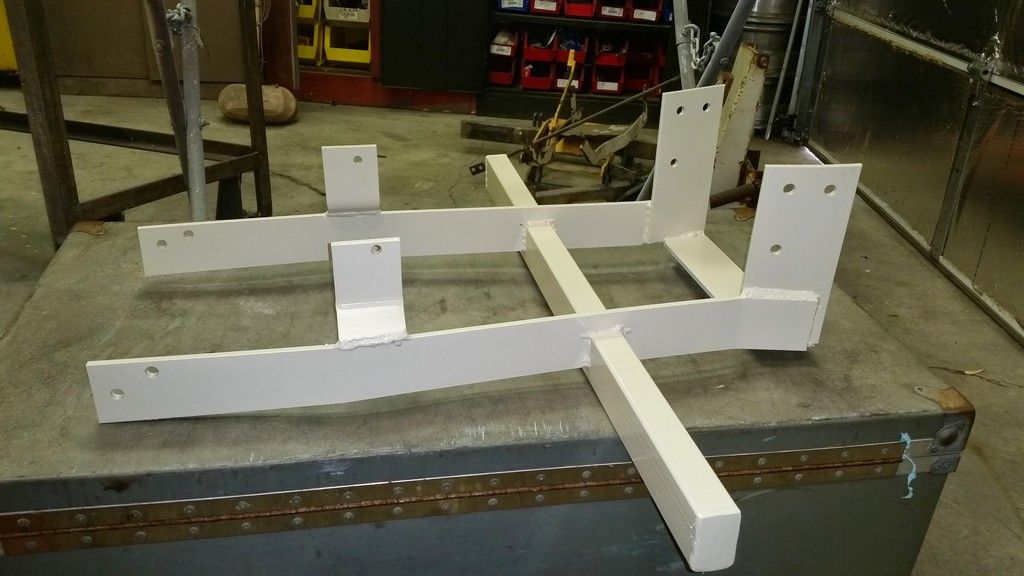

Here is a pic of the wings I'm going to add, my loader came with no forward down supports, so I have to build those also. There will be a vertical bolt to fasten the down support. Support will have a flat plate welded to the round rod. Overkill? Probably so

|

|

#68

|

||||

|

||||

|

__________________

149 with kwik-way loader,1772,two 1782 super smokers, 982 SGT w 54" haban blade,60" haban deck, 50in deck cat 0 3 point, brinly cat 0: blade, plow(3), disc.123,hydro lift. 61"O" Brinly single row planter,brinly cultivator,#2 trailer,brinly 10 inch plow,3 42 inch blades,Model #1 Tiller with extenstions,haban sickle mo. 106w/ags and hydro lift.

|

|

#69

|

|||

|

|||

|

Thanks for the pump pics!

I have to source a pump for mine as it came with no pump or controls. A buddy of mine said he has a loader control valve I can have, would like to get a valve with a float position but I'll take what ever he is giving away! Attached is a pic of the bottom mounts with the studs (1/2" bolts w/head cut off) welded on, I'm surprised at how solid this setup is! |

|

#70

|

|||

|

|||

|

Ok, moving on to the hydraulics. Spent this evening looking at everything I could find on the net about the pump to use with this loader. Seems the stock pump is a MTE C210 pump, I'm going to go with the D210 version as it appears to be the same pump, will be pulley driven (I know it's suppose to be a direct drive pump, doubt I'll wear it out in my lifetime with any side loading)

Comments on pump selection? To fast or to slow from those using the 210? Next up suction strainer, from the pics I have seen not to many are running a suction filter? Are you using a strainer somewhere in the suction line? My reservoir appears to have been sitting with water in it as it was bulged out (assume frozen over winter sometime) and had to be flattened back down in my hydraulic press. So with that known I have gotten of rust out and will need to run a strainer of some type and now would be the time to weld in a larger bung for one or find one that fits in the existing bung. So what are you all using for a strainer/filter? |

|

|

|

Cub Cadet is a premium line of outdoor power equipment, established in 1961 as part of International Harvester. During the 1960s, IH initiated an entirely new line of lawn and garden equipment aimed at the owners rural homes with large yards and private gardens. There were a wide variety of Cub Cadet branded and after-market attachments available; including mowers, blades, snow blowers, front loaders, plows, carts, etc. Cub Cadet advertising at that time harped on their thorough testing by "boys - acknowledged by many as the world's worst destructive force!". Cub Cadets became known for their dependability and rugged construction.

MTD Products, Inc. of Cleveland, Ohio purchased the Cub Cadet brand from International Harvester in 1981. Cub Cadet was held as a wholly owned subsidiary for many years following this acquisition, which allowed them to operate independently. Recently, MTD has taken a more aggressive role and integrated Cub Cadet into its other lines of power equipment.

This website and forum are not affiliated with or sponsored by MTD Products Inc, which owns the CUB CADET trademarks. It is not an official MTD Products Inc, website, and MTD Products Inc, is not responsible for any of its content. The official MTD Products Inc, website can be found at: http://www.mtdproducts.com. The information and opinions expressed on this website are the responsibility of the website's owner and/or it's members, and do not represent the opinions of MTD Products Inc. IH, INTERNATIONAL HARVESTER are registered trademark of CNH America LLC

All material, images, and graphics from this site are the property of www.onlycubcadets.net. Any unauthorized use, reproductions, or duplications are prohibited unless solely expressed in writing.

Cub Cadet, Cub, Cadet, IH, MTD, Parts, Tractors, Tractor, International Harvester, Lawn, Garden, Lawn Mower, Kohler, garden tractor equipment, lawn garden tractors, antique garden tractors, garden tractor, PTO, parts, online, Original, 70, 71, 72, 73, 76, SO76, 80, 81, 86, 100, 102, 104, 105, 106, 107, 108,109, 122, 123, 124, 125, 126, 127, 128, 129, 147, 149, 169, 182, 282, 382, 482, 580, 582, 582 Special, 680, 682, 782, 782D, 784, 800, 805, 882, 982, 984, 986, 1000, 1015, 1100, 1105, 1110, 1200, 1250, 1282, 1450, 1512, 1604, 1605, 1606, 1610, 1615, 1620, 1650, 1710, 1711, 1712, 1806, 1810, 1811, 1812, 1912, 1914.