|

PLEASE PATRONIZE OUR SPONSORS!

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

This is kind of a continuation of this thread;

http://onlycubcadets.net/forum/showthread.php?t=29867 As I was completing the install of the windbreaker today, I did a small modification to the H42. The P.O. had the shoes raised to the highest point, this left the scrapper bar about 2" off of the concrete. The sections of my driveway seem to heave this time of year, and if the scrapper is set too low the blower catches the joints and jolts violently. I believe this contributed to the death of the QA36A. So in an effort to get a clean wipe on the concrete, but but hammer the scrapper bar on the joints in the driveway, I added 2.5" hard rubber sections in front of the scrapper bar.    It worked pretty good.  Trying not to get too concerned that I sheared (2) shear pins today. Time will tell if it was a fluke, or a problem. |

|

#2

|

||||

|

||||

|

Wow, good idea, actually!

As far as the sheer pins go, losing 2 in a day is almost a red flag right there. Keep us posted, I'm curious how this rubber scraper for a thrower will work out.

__________________

-Ryan

|

|

#3

|

||||

|

||||

|

Well I'm not loving the H42. I cannot seem to keep the auger turning. It will be hard to capture all the events I had with this problem, but here goes nothing.

As you may recall, it was missing (1) of the shear pins when I bought it. The one where the driveshaft comes off of the right angle gearbox. I stopped at Aldermans on my way home, they had (3) in stock, I bought all (3). The first time out blowing snow, I lose the pin on the opposite end of the driveshaft. I install one of the extras I had. That one lasts about 20 minutes. The next day I find it, it did not shear, it just "came" out. It is the bent one in this picture. So it appears that the cotter pin will not hold it in, so I safety wire the next one, you can see that one in the picture also. Funny thing is The safety wire one came out, while I was standing next to the tractor, with the pto engaged! I was curious how much slop the driveline had in it, so I engaged the PTO and was looking it over, the snap crackle pop, pin and wire laying on the drive way!  . . So then I move on the 1/4 - 20 hex bolts, same thing, engage PTO, wait for it, snap crackle pop, nut and bolt laying on driveway! Ok, its on now, this is becoming personal, 1/4 - 20 bolt, and (2) nuts! Jam nutted together. Guess what? Yep, engage PTO, step back and wait, snap crackle pop, (2) nuts, and (1) bolts bouncing accross the driveway! I swear, you can't make this stuff up!  So now I pull my hat down a little tighter, set my jaw and bust out my MIG welder! Nice fat tack welds, holding the nuts onto the bolts! No easy task, if you ever attempted to service these things, they are not real accessible. But this aint my first rodeo, I get enough weld, on them, to ensure the nuts will not be leaving the bolts. So away we go, back to moving snow, for about 30 minutes. Then the story takes a sad turn;  Sooooo I'm not sure what to do next? The driveshaft really does not appear to have very much slop in it, I'm at a loss to understand why this keeps happening? http://www.youtube.com/watch?v=qH_9G...ct0XSNEN-PnFyg Kind of sad having that snow moving beast, and having to break out the shovel!

|

|

#4

|

||||

|

||||

|

Not trying to hone in on your thread just thought to commiserate. You really are having a hard time of it, my problems are similar but not exactly. I just got my 682 and H42 this year, they did not come as a package. I had trouble keeping the first shear pin out of the gear box in for a couple of weeks, using the snap ring that they are supposed to use to retain them, like you said at first the rings kept coming off I guess?? and the pin would be laying on the driveway, I went to a cotter pin. That has seemingly solved that problem (cross my fingers) then the pulley on the back of the gear box starts coming off, mine has 2 set screws at 90 degrees to each other, one of which tightens onto a key, I tried loctite several times, out the barn we go, stops blowing, back up there lays the pulley on the driveway, this happens twice at least, I notice there is a hole all the way through the shaft to line up with the set screw that doesn't hit the key. I slide a 1/4 drill bit through that hole and out the other side of the pulley, insert a 1/4 20 bolt with nylon locnut, couple times out snaps that bolt. I notice that the pulley must really be worn out on the inside as it really wobbles on the shaft until I tighten the set screw. I shim it up with brass as much as I can, tighten the set screw on the key and install a grade 8 bolt with locnut. That has held for about 10 days now, the key is gone again, the shims are gone and of course, I am just hoping to get through the season so I can properly take it all down, determine whether the shaft is ok (I really hope so) replace that pulley for next year so that if fits tight on the shaft. My gut tells me that the point when the pto is engaged is where most of the damage is happening, I have taken to engaging the pto at low rpm then taking it up, I also kick the auger to make sure it is loose before I start the tractor, I wonder if sometimes it wasn't froze solid with packed snow / ice? These things really are beasts, when they are running they are great and I guess it's not too hard to understand "wear" after 30 years, hope you can get yours running, hate the shovel! Best of luck!

Vic |

|

#5

|

||||

|

||||

|

Quote:

The previous owner must have lost the 3/16" key (35 in the pic), and replaced it with a shear pin? I'll get a key, and restore that end to the factory design. That doesn't help with the shear pin on the other end of the shaft; (12 in the pic)

|

|

#6

|

|||

|

|||

|

Hi MWShaw,

I just stumbled on your thread because I have been getting somewhat frustrated with shearing bolts on my snow thrower. I have a H48 mounted on a 1641. And unfortunately I regularly snap bolts. I use the regular grade 2 bolts and lock-nuts and sometimes I am good for a half hour, other times about 5 minutes. When I bought the thrower, I don't know if I even had a true shear pin in it. I am tempted to use a grade 5 bolt because I spend more time crawling around changing the bolts than anything else. I also do not snug the nut up tight, just far enough on the nylon to keep it from backing out. I have rad that slop will shear the pin quickly too... Anyway, what caught my eye about your post is that I also replace the bolts at the gear box end of the arm. And I am missing the Parallel Key on mine too. But I am not sure why it's not 6 of one and half a dozen of the other? I find it easier access the gear box end then the end of the arm under the shield. Do you know if I am sabotaging the set up by making the weakest link by the gear box? Also I noticed in the picture of your actual shear pins, they seem to be clevice pins, without any groove etched into them. I can actually get some of those at Lowes, is that a type of shear pin I should perhaps be using? When this system works, it's great. But when it fails without a consistent pattern, then it is frustrating. Anyway, I will keep reading what gets posted. thanks. |

|

#7

|

||||

|

||||

|

Quote:

From looking at the skematic, I believe the design intent was for the weak link to be the shear pin at the gearbox. The picture of my shear pins, is the ones that my Cub dealer sold me. I believe those are the #12 in the skematic pictures. Yes it is a great system, but I'm getting very frustrated with it. I thought I was making a step up from my QA36A, but I never had this much trouble with that one. Speaking of the QA36A, mine had no shear pins that I am aware of. The weak link on that was the belt, if it plugged with snow or caught the impleller on something, the belt would slip. So that may be what I do with this one, use grade 8 cap screws instead of shear pins, add a few 3/8-16 set screws to each end of the driveshaft and let the belt be the weak link? |

|

#8

|

||||

|

||||

|

I pulled the gearbox off of the thrower today. I believe the root of the shear pin issue is a design flaw.

The holes in the gearbox shaft are .295", the shear pin diameter is .248". That is .047" of slop between the pin and the i.D. of the hole. I can see where it would just hammer back and forth, until the pin broke. The reason I am quite sure its a design flaw, and not a whopped out hole, is this gearbox has (2) shafts exiting it, (1) of those has never been used, both shafts have holes in them that are the same I.D.

|

|

#9

|

||||

|

||||

|

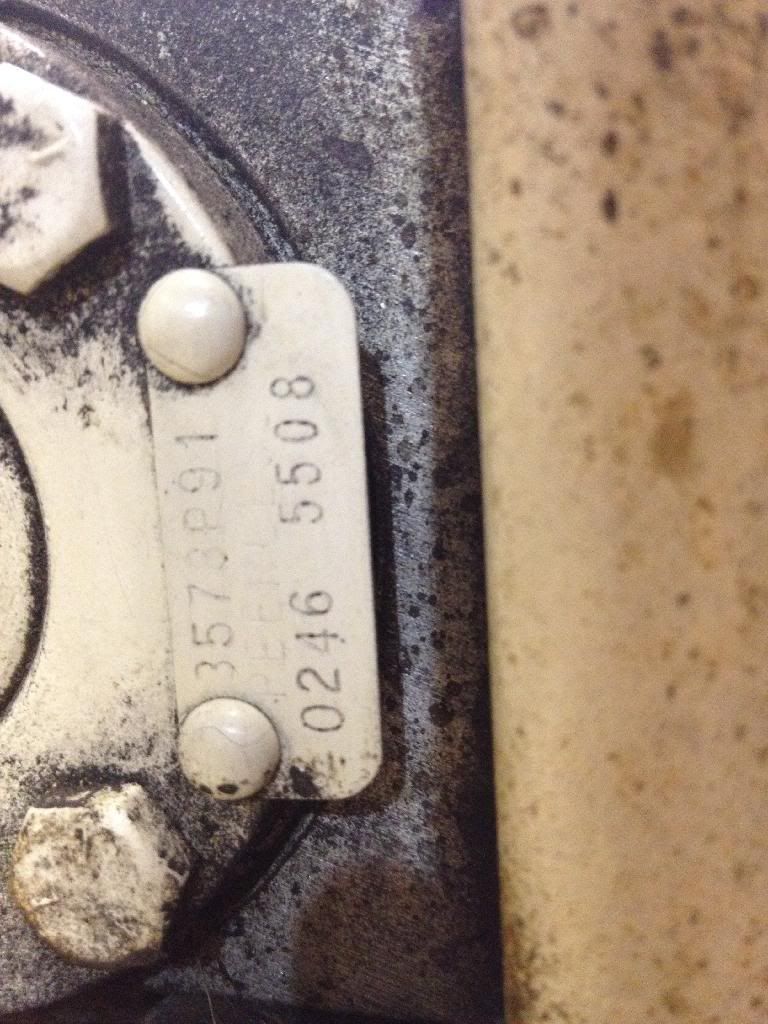

Anyone ever hear of a "Peerless" gearbox? That what is on this Haban thrower.

|

|

#10

|

||||

|

||||

|

So I decided that I'm not a fan of shear pins. The QA36A didn't have them (that I know of?). So I made a decision to key both ends of the driveshaft.

I may regret it later, but the attachment is absolutely useless to me, when it is shearing pins constantly. Time will tell.

|

|

|

|

Cub Cadet is a premium line of outdoor power equipment, established in 1961 as part of International Harvester. During the 1960s, IH initiated an entirely new line of lawn and garden equipment aimed at the owners rural homes with large yards and private gardens. There were a wide variety of Cub Cadet branded and after-market attachments available; including mowers, blades, snow blowers, front loaders, plows, carts, etc. Cub Cadet advertising at that time harped on their thorough testing by "boys - acknowledged by many as the world's worst destructive force!". Cub Cadets became known for their dependability and rugged construction.

MTD Products, Inc. of Cleveland, Ohio purchased the Cub Cadet brand from International Harvester in 1981. Cub Cadet was held as a wholly owned subsidiary for many years following this acquisition, which allowed them to operate independently. Recently, MTD has taken a more aggressive role and integrated Cub Cadet into its other lines of power equipment.

This website and forum are not affiliated with or sponsored by MTD Products Inc, which owns the CUB CADET trademarks. It is not an official MTD Products Inc, website, and MTD Products Inc, is not responsible for any of its content. The official MTD Products Inc, website can be found at: http://www.mtdproducts.com. The information and opinions expressed on this website are the responsibility of the website's owner and/or it's members, and do not represent the opinions of MTD Products Inc. IH, INTERNATIONAL HARVESTER are registered trademark of CNH America LLC

All material, images, and graphics from this site are the property of www.onlycubcadets.net. Any unauthorized use, reproductions, or duplications are prohibited unless solely expressed in writing.

Cub Cadet, Cub, Cadet, IH, MTD, Parts, Tractors, Tractor, International Harvester, Lawn, Garden, Lawn Mower, Kohler, garden tractor equipment, lawn garden tractors, antique garden tractors, garden tractor, PTO, parts, online, Original, 70, 71, 72, 73, 76, SO76, 80, 81, 86, 100, 102, 104, 105, 106, 107, 108,109, 122, 123, 124, 125, 126, 127, 128, 129, 147, 149, 169, 182, 282, 382, 482, 580, 582, 582 Special, 680, 682, 782, 782D, 784, 800, 805, 882, 982, 984, 986, 1000, 1015, 1100, 1105, 1110, 1200, 1250, 1282, 1450, 1512, 1604, 1605, 1606, 1610, 1615, 1620, 1650, 1710, 1711, 1712, 1806, 1810, 1811, 1812, 1912, 1914.